Garage door openers often continue to function even as internal stress quietly increases across multiple connected components. Movement may appear smooth, controls may respond as expected, and daily operation may feel unchanged for long periods. These conditions create a false sense of reliability that hides developing mechanical and electrical strain. Over time, the system compensates for imbalance, resistance, or alignment issues without immediately signaling obvious failure.

The need for garage door repair services frequently emerges only after hidden strain reaches a point where compensation is no longer possible. Subtle changes accumulate inside the system while outward performance appears stable. Understanding why these invisible shifts occur helps explain why repairs become necessary without dramatic warning signs. The absence of clear failure does not indicate the absence of risk.

Hidden Mechanical Stress Inside the Opener System

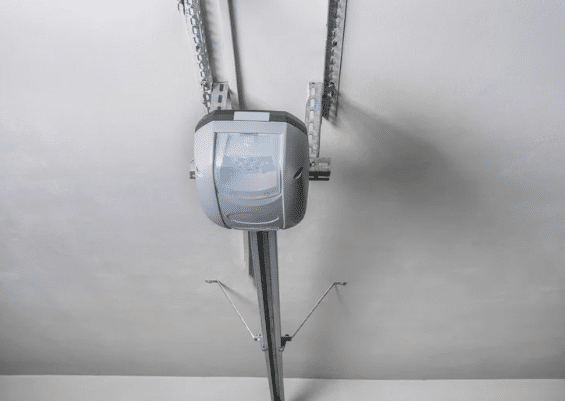

Garage door openers function as part of a larger mechanical system rather than as isolated devices. When doors move unevenly or components shift slightly, the opener absorbs added resistance. This internal stress builds gradually and often goes unnoticed. Garage door opener repair often becomes necessary when hidden strain finally affects performance consistency.

Mechanical stress does not always produce noise or sudden stoppage. Instead, it quietly changes how force is distributed during operation. Over time, this imbalance affects internal gears, drive systems, and motor components.

Find out the early warning patterns that commonly signal the need for garage door opener repair before a complete failure occurs by reading: Early Warning Patterns That Often Lead to Garage Door Opener Repair.

Subtle Sources of Internal Mechanical Strain

- The door weight is increasing gradually due to moisture absorption or panel aging.

- Springs are losing balance while still allowing the door to move.

- Rollers are creating uneven resistance across the track system.

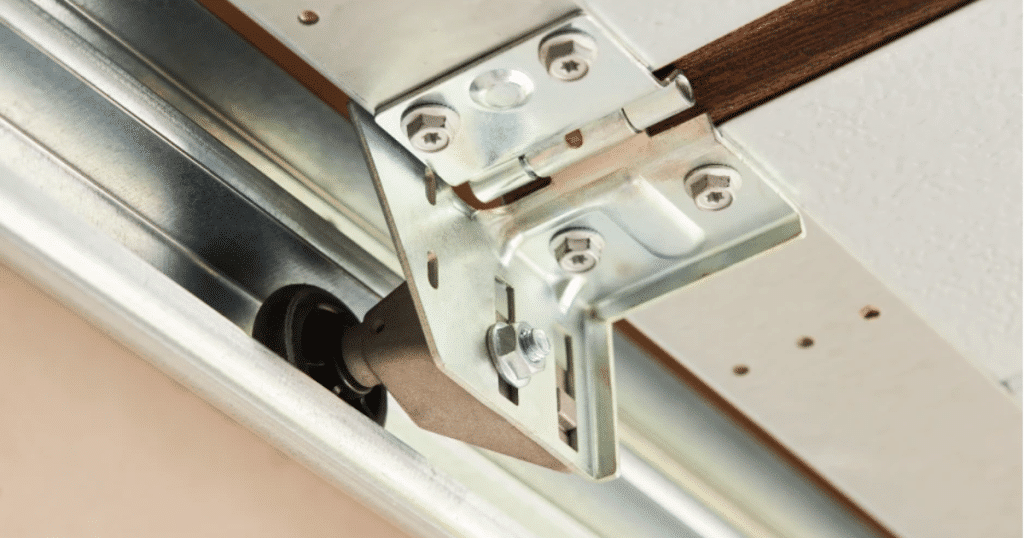

- Tracks are shifting slightly and altering travel alignment.

- Hinges are loosening and transferring load inconsistently.

- Cables are stretching unevenly without visible damage.

These conditions often develop slowly, allowing the opener to compensate temporarily. That compensation increases internal wear without clear external symptoms. Recognizing these sources explains why repairs become necessary even when failure seems sudden.

Learn how garage door opener repair is closely connected to balance, alignment, and door weight issues that affect overall performance by reading: How Garage Door Opener Repair Is Linked to Balance, Alignment, and Door Weight.

Electrical Wear That Does Not Trigger Immediate Failure

Electrical components inside garage door openers degrade differently from mechanical parts. Circuits, capacitors, and wiring connections weaken over time without producing obvious signs. Garage door opener repair often addresses electrical fatigue that develops long before a visible malfunction.

Unlike mechanical failure, electrical wear often affects reliability rather than outright function. Systems may work intermittently or respond inconsistently before stopping entirely. These patterns make early detection difficult without professional evaluation.

Explore what repeated shutdowns, sensor errors, and inconsistent operation reveal about underlying garage door opener repair needs by reading: What Repeated Shutdowns and Sensor Errors Reveal About Garage Door Opener Repair Needs.

Electrical Conditions That Progress Quietly

- Circuit boards are experiencing gradual heat-related degradation.

- Capacitors are losing efficiency while still powering basic functions.

- Wiring connections loosen through vibration over repeated cycles.

- Control boards compensate for voltage fluctuations.

- Sensors are communicating inconsistently, but not fully failing.

- Power surges cause incremental component damage.

Each condition weakens reliability while allowing continued operation. Over time, accumulated electrical wear leads to unpredictable behavior. Repair becomes necessary once system stability declines beyond acceptable limits.

Compensation Masks Problems Until Limits Are Reached

Garage door opener systems are designed to compensate for moderate resistance and imbalance. This adaptability improves convenience but also delays the appearance of visible warning signs. Garage door opener repair is often necessary when the compensation capacity is exhausted.

As compensation increases, internal components operate under a higher load. Motors draw more power, gears experience greater friction, and electronics manage rising demand. These adjustments conceal developing problems until a sudden malfunction occurs.

Ways Compensation Delays Obvious Symptoms

- Motors increasing torque output to overcome resistance.

- Drive systems absorb vibration without immediate noise.

- Force settings adjust automatically within safety limits.

- Sensors tolerate slight alignment inconsistencies.

- Control logic retrying operations after minor interruptions.

- Safety systems remain inactive despite growing stress.

Compensation allows daily operation to continue while internal damage accelerates. When limits are exceeded, failures appear abrupt. Understanding compensation explains why warning signs remain subtle for extended periods.

Installation Factors That Influence Delayed Repair Needs

The quality of garage door opener installation strongly affects when problems first appear. Even minor setup deviations can alter long-term system behavior. Garage door opener repair frequently traces back to installation choices made years earlier.

Improper alignment, force calibration, or mounting stability may not cause immediate problems. Instead, they introduce low-level stress that accumulates slowly. These hidden effects surface later as unexpected repair needs.

Installation Choices With Long-Term Consequences

- Opener mounted slightly off-center relative to door travel.

- Force limits are set too high during initial adjustment.

- Rail alignment allows minor binding during operation.

- Attachment points flexing under repeated load.

- Travel limits are configured without a precise door balance.

- Safety sensors positioned with minimal tolerance margin.

These choices allow the system to function initially but reduce long-term stability. Over time, stress concentrates in vulnerable areas. Repair becomes necessary once accumulated effects compromise reliability.

Interaction Between Door Balance and Opener Health

Garage door openers rely heavily on proper door balance for safe operation. When balance shifts, the opener compensates silently. Garage door opener repair often becomes necessary when balance issues persist unnoticed.

Balanced doors reduce load on motors and drive systems. Imbalance increases energy demand and wear. Because imbalance develops gradually, it often escapes attention until damage occurs.

Balance-Related Conditions That Affect Openers

- Springs are losing tension unevenly across the shaft.

- Door panels are warping, affecting the weight distribution.

- Hardware wear alters pivot points.

- Track resistance is increasing on one side of the door.

- Cable stretch creates asymmetrical lifting forces.

- Seasonal temperature changes affect spring performance.

Each condition subtly increases the opener’s workload. Compensation hides imbalance while accelerating internal wear. Repair becomes necessary once the imbalance overwhelms the system’s tolerance.

Why Warning Signs Often Appear Inconsistent

Early symptoms of opener problems rarely appear consistently, but failing to address them can prompt homeowners to get a new garage door. One cycle may feel normal while another behaves differently. Garage door opener repair frequently follows patterns of intermittent behavior that confuse users.

Inconsistency results from fluctuating resistance, electrical variability, or environmental influence. These factors interact unpredictably, masking underlying causes. Understanding inconsistency helps explain delayed response to emerging issues.

Causes of Inconsistent Opener Behavior

- Temperature changes affect metal expansion and contraction.

- Variable friction depending on door position.

- Electrical fluctuations influencing motor performance.

- Sensor sensitivity changes with lighting conditions.

- Minor obstructions intermittently affect track travel.

- Control logic resets after temporary overloads.

Regardless of the type of garage door installed, one thing is for sure: inconsistent behavior delays recognition of developing problems. Over time, these fluctuations grow more frequent and severe. Repair becomes necessary once an inconsistency turns into failure.

The Role of Professional Evaluation in Early Detection

Professional evaluation identifies risks that are difficult to recognize through casual observation. It is not just about knowing how garage door installation works, but also assessing the overall performance of the garage door. Technicians assess system interaction rather than isolated symptoms. Garage door opener repair often becomes necessary after evaluations reveal hidden stress patterns.

Evaluations focus on balance, alignment, electrical response, and mechanical wear. These factors rarely produce dramatic symptoms until advanced stages. Professional insight helps detect problems before sudden failure.

Areas Evaluated During Professional Inspection

- Motor load during various door positions.

- Door balance relative to the opener force output.

- Drive system wear under dynamic conditions.

- Sensor reliability across lighting variations.

- Electrical response to repeated cycling.

- Structural stability of mounting hardware.

These assessments reveal developing issues well before complete failure. Early detection supports safer operation and prevents sudden breakdowns. Understanding evaluation value explains why repairs sometimes seem unexpected.

Long-Term System Stability Through Ongoing Oversight

Garage door opener systems require ongoing attention to maintain long-term reliability. Garage door opener repair addresses problems that develop silently due to mechanical, electrical, and environmental interactions. Awareness of hidden warning patterns supports better system care.

When subtle changes are recognized early, repair needs remain manageable rather than urgent. Understanding how problems develop without clear failure signs helps maintain stability over time. Consistent oversight preserves system performance and reduces unexpected disruption.

BSD Garage Door, LLC provides professional garage door installation, repair, and maintenance services backed by years of hands-on experience. Every service is designed to improve home safety, functionality, and long-term value. Experienced technicians service all major garage door brands using high-quality parts and tools. Efficient workmanship ensures dependable results for both repairs and replacements.

Contact us today or give us a call to schedule trusted garage door service.

Frequently Asked Questions

Garage door openers can continue operating even as internal components wear down. We often see motors, gears, or electronics compensating for stress without obvious symptoms. This hidden strain allows the opener to function while reliability quietly declines. Repair becomes necessary before complete failure occurs.

Not all internal wear produces sound immediately. We frequently find gear wear, circuit board issues, or motor fatigue developing silently. These components can degrade gradually without grinding or clicking. By the time noise appears, damage is often advanced.

Intermittent operation is often linked to electrical or sensor-related issues. We commonly see wiring wear, failing capacitors, or heat-related shutdowns cause inconsistent behavior. The opener may work one moment and fail the next. This inconsistency is an early indicator that repair is needed.

An unbalanced door places extra demand on the opener during every cycle. We often see openers compensating quietly for added resistance. This extra workload does not always feel dramatic at first. Over time, it accelerates internal wear and increases the need for repairs.

Openers are designed to stop when resistance exceeds safe limits. We frequently see force settings activate due to gradual increases in friction or imbalance. The opener protects itself by intermittently shutting down. These responses signal underlying issues that require attention.

Temperature changes, humidity, and dust can affect electronic components over time. We often see corrosion or heat stress reduce efficiency without immediate symptoms. Seasonal conditions can slowly weaken internal parts. Repair becomes necessary even though failure seems sudden.

A lag between pressing the button and door movement often reflects electrical wear. We frequently find control boards or internal relays beginning to fail. These delays are subtle but meaningful. Addressing them early helps prevent total shutdown.

Openers are built to guide smooth, balanced doors. We often see a reduced lifespan when the opener compensates for door-related issues over the long term. This strain happens quietly with each cycle. Repair becomes necessary once internal tolerance is exceeded.

Early symptoms often feel minor or inconsistent. We frequently see homeowners adapt to slower movement or occasional hesitation. These changes become normalized over time. The underlying problem continues to develop unnoticed.

Early repair addresses internal wear before multiple components are damaged. We often see simpler, less expensive repairs when issues are caught early. Waiting usually leads to complete opener failure and replacement. Proactive repair preserves reliability and avoids sudden loss of access.