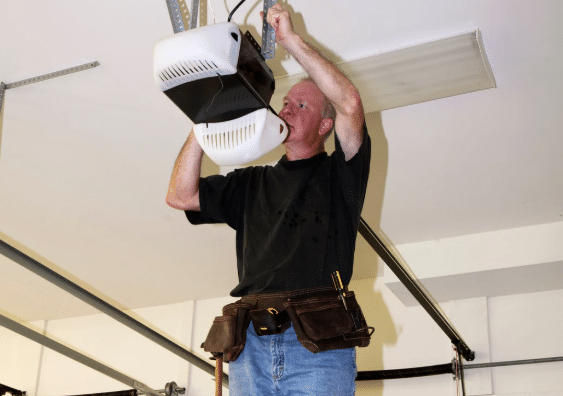

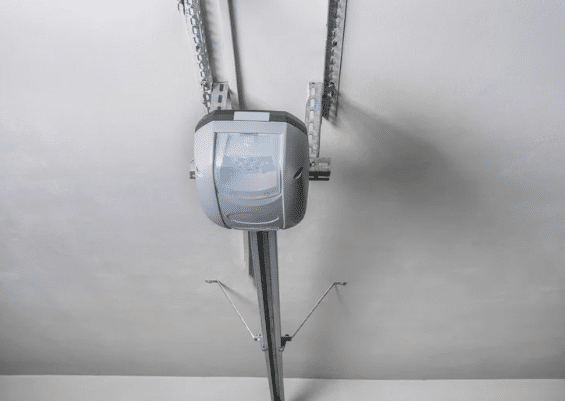

Garage door opener systems rarely fail without first showing subtle behavioral changes that seem harmless during everyday use. These early patterns often appear inconsistently, making them easy to dismiss or misinterpret as temporary quirks. Over time, those small changes become more frequent as underlying stress builds across mechanical and electrical components. Recognizing these patterns early helps explain why garage door opener repair is often required before a complete breakdown occurs.

Many early warning signs do not involve the door stopping completely or refusing to respond to controls. Instead, they involve timing changes, unusual responses, or slight shifts in how the system feels during operation. If the door keeps opening and closing, these patterns may not feel urgent, but a garage door tune-up will reveal that there are underlying conditions that need immediate attention. Understanding how these signals develop provides valuable insight into long-term system reliability.

Changes in Movement Speed and Rhythm

One of the earliest patterns involves changes in how quickly or smoothly the door moves during operation. The door may still complete its cycle, but timing variations begin appearing. These changes often indicate growing resistance or internal strain that the opener quietly compensates for. Garage door opener repair frequently becomes necessary once these rhythm changes persist.

Variations in movement speed rarely occur uniformly throughout the cycle. Certain sections of travel may feel slower or less controlled. These changes signal uneven load distribution or motor strain developing over time.

Find out why garage door opener repair can become necessary even when there are no obvious signs of failure by reading: Why Does Garage Door Opener Repair Become Necessary Without Clear Failure Signs?

Movement Patterns That Signal Developing Problems

- Door movement is slowing near the midpoint of travel.

- Uneven speed between opening and closing cycles.

- Hesitation before movement begins after activation.

- Slight jerking motions during otherwise smooth travel.

- The door is completing cycles but taking longer than usual.

- Movement speed varies with temperature.

These patterns suggest that internal resistance is increasing gradually. Compensation masks the issue temporarily while wear accelerates inside the system. Repair becomes necessary once compensation reaches its limits.

Learn how garage door opener repair is often tied to balance issues, alignment problems, and improper door weight by reading: How Garage Door Opener Repair Is Linked to Balance, Alignment, and Door Weight.

Inconsistent Response to Controls

Another early warning pattern involves delayed or inconsistent responses when using wall controls or remote devices. The opener may respond correctly sometimes while ignoring commands at other moments. Garage door opener repair often follows periods of unreliable responsiveness that seem random.

Control inconsistency usually reflects communication issues rather than total electrical failure. Signal processing, wiring connections, or control boards may be struggling under fluctuating conditions. These inconsistencies often worsen gradually.

Explore what repeated shutdowns, sensor errors, and inconsistent operation reveal about deeper garage door opener repair needs by reading: What Repeated Shutdowns and Sensor Errors Reveal About Garage Door Opener Repair Needs.

Control Response Irregularities to Watch For

- Delayed response after pressing the wall-mounted controls.

- Remote commands work only at closer distances.

- Need to press buttons multiple times for activation.

- Door stopping briefly before completing a command.

- Controls responding inconsistently at different times of day.

- Opener activating after noticeable hesitation.

Whether it is a broken garage door sensor or a malfunctioning spring, these behaviors indicate early electrical or communication issues. Continued operation under these conditions increases internal stress. Repair becomes necessary when responsiveness degrades further.

Unusual Sounds That Appear Intermittently

Sound changes often appear before visible failure, though they may come and go unpredictably. These noises often emerge under specific conditions rather than consistently. Garage door opener repair often follows periods of intermittent sound changes that seem minor at first.

Unlike sudden, loud failures, early, subtle changes are situational. They may occur only during certain parts of the cycle. Paying attention to when sounds occur helps identify developing issues. No matter the type of garage door installed, unusual sounds indicate a serious problem that requires professionals.

Sound Patterns That Indicate Internal Wear

- Low humming sounds that increase during lifting.

- Clicking noises when the motor engages or disengages.

- Brief grinding sounds that stop quickly.

- Rattling noises during initial movement.

- Buzzing sounds when the opener holds position.

- Sounds change with the door position or direction.

These sounds reflect internal components compensating for stress. Ignoring them allows wear to progress unnoticed. Repair becomes necessary once sounds grow more frequent or persistent.

Changes in Safety Sensor Behavior

Safety sensors play a critical role in opener operation, and early sensor issues often appear subtly. Sensors may continue functioning while communicating inconsistently. Garage door opener repair often addresses sensor-related issues before a complete shutdown.

Early sensor problems do not always cause immediate reversal or shutdown. Instead, they create intermittent interruptions that seem unexplained. These interruptions indicate communication or alignment challenges.

Sensor-Related Warning Patterns

- Door reversing briefly without visible obstruction.

- Sensors require frequent cleaning to function normally.

- The system occasionally refuses to close without a clear cause.

- Sensitivity changes depending on lighting conditions.

- Door closing normally after multiple attempts.

- Indicator lights flickering or changing color intermittently.

These behaviors suggest that sensors are compensating for alignment or signal issues. Over time, reliability declines further. Repair becomes necessary once safety responses activate unpredictably.

Force Adjustment and Strain Compensation Indicators

Modern openers automatically adjust force output to manage resistance. Early warning patterns often involve force compensation becoming more noticeable. Garage door opener repair becomes necessary when force adjustments exceed safe operating limits.

Force-related patterns often feel subtle, such as increased effort during lifting. These changes reflect growing imbalance or resistance within the system.

Signs of Force Compensation at Work

- Opener working harder during the lift than during the lower.

- Door pausing briefly under heavier load sections.

- Motor sounds strained during certain movements.

- Increased vibration during operation.

- Door requiring manual assistance occasionally.

- Force settings are reaching higher thresholds over time.

These indicators show that the opener is compensating for a mechanical imbalance. Continued strain accelerates wear. Repair becomes necessary once force compensation becomes unreliable.

Environmental Influence on Early Warning Signs

Environmental conditions often amplify early warning patterns. Temperature, humidity, and seasonal changes affect system behavior. Garage door opener repair frequently follows seasonal shifts that expose underlying weaknesses.

These influences create variability that masks consistent symptoms. Observing patterns across conditions provides better insight into system health.

Environmental Factors That Reveal Hidden Issues

- Cold temperatures increase stiffness and resistance.

- Heat affects electrical responsiveness and timing.

- Humidity influences door weight and balance.

- Seasonal expansion ais ffecting track alignment.

- Weather changes are impacting sensor performance.

- Daily temperature swings alter movement consistency.

Environmental stress reveals issues that remain hidden under stable conditions. Over time, these effects compound. Repair becomes necessary when environmental tolerance decreases.

Gradual Decline in Overall System Reliability

The accumulation of early warning patterns results in declining reliability rather than sudden failure. Garage door opener repair often addresses systems that still function but no longer operate consistently. Reliability decline signals the final stage before major malfunction.

This stage involves more frequent disruptions without a clear cause. Understanding this progression helps explain why repairs seem unexpected.

Reliability Decline Patterns

- Increased frequency of minor operational issues.

- Reduced confidence in consistent daily operation.

- Need for repeated resets or adjustments.

- Growing unpredictability during normal use.

- Multiple minor symptoms appear together.

- System performance varies from day to day.

These patterns indicate that the system is approaching failure thresholds. Repair becomes necessary to restore stability and prevent sudden breakdowns.

Preserving Long-Term Performance Through Early Awareness

Early warning patterns offer valuable insight into system health long before complete failure occurs. Garage door opener repair addresses these patterns when intervention remains manageable rather than urgent. Recognizing subtle changes supports safer and more reliable operation.

Understanding how these warning signs develop encourages proactive evaluation rather than reactive response. Long-term system stability depends on recognizing early signals and addressing them thoughtfully. Awareness helps maintain consistent performance while reducing unexpected disruptions.

BSD Garage Door, LLC delivers reliable garage door services focused on performance, safety, and durability. Installation, maintenance, and repair services are completed by skilled professionals equipped to work on all major brands and models. Quality materials and proven techniques support smooth operation and long-lasting results. Each project is handled with precision and care.

Contact us today or give us a call for expert garage door solutions.

Frequently Asked Questions

Early patterns usually appear as subtle changes in how the opener responds during daily use. We often see slight delays, hesitations, or gradual inconsistencies rather than sudden ones. These patterns indicate the buildup of internal strain before a full failure occurs.

Inconsistent operation often means the opener is compensating for resistance or internal wear. We frequently see this happen when gears, sensors, or electrical components begin weakening. Over time, inconsistency becomes more frequent as the system struggles to maintain normal performance. This is why, at the onset, it is important to know how garage door installation works.

A noticeable delay between pressing the button and the door moving often indicates electrical or motor-related wear. We commonly find control boards, relays, or capacitors beginning to degrade. Slower response is rarely random and usually signals developing internal issues.

Safety reversals often occur when the opener senses abnormal resistance during movement. We frequently see this linked to door imbalance or rising friction that strains the opener. When reversals happen repeatedly, the opener is signaling that conditions are no longer within safe limits.

An opener that works one moment and fails the next often indicates electrical instability. We commonly see wiring wear, heat-related shutdowns, or sensor communication issues behind this pattern. Intermittent behavior is a strong indicator that repair should not be delayed.

Excessive vibration often means internal gears or mounting components are no longer operating smoothly. We frequently see vibration increase as parts lose alignment or wear unevenly. This pattern usually appears before a more obvious mechanical failure.

New humming, clicking, or buzzing sounds often reflect motor or gear stress. We commonly see these sounds appear before grinding or loud failure noises develop. Early noise changes signal that internal components are working harder than they were designed to.

Flickering lights or delayed control response often indicate electrical wear inside the opener. We frequently find control boards or wiring connections beginning to fail. These patterns suggest repair is needed even if door movement still seems acceptable.

Each cycle adds stress to already-strained opener components. We often see minor issues become consistent problems as daily use continues. Repeated operation accelerates wear until repair becomes unavoidable.

Early warning patterns allow repairs to address internal wear before multiple components fail. We frequently see simpler, more affordable repairs when action is taken early. Recognizing these signs helps preserve reliability and avoid sudden loss of garage access.